1. REGULAR RACK SURVEY’S AND AUDITS

Internationally published racking standards (EN, SEMA, etc.) recommend annual surveys be undertaken by ‘technically component’ individuals. The annual survey serves as an external audit of the racking safety and suitability for use. Annual surveys form a complement to in-house maintenance protocols as stipulated by the standard being followed.

Annual survey services offered by BMH include Engineer’s Surveys and Non-Compliance Surveys, along with the associated reports. Both consist of an inspector attending the site to undertake a ground level, visual inspection of the racking installation. If the installation had not been previously certified, component measurements and frame elevations will be taken to evaluate the suitability of the frames to support the design loads.

The primary difference between Engineer’s and Non-Compliance Surveys are the level of detail to which these inspections are performed.

Engineer’s Surveys consist of inspecting and measuring a statistically significant number of total locations in the store to gain a general understanding of the condition of the installation. Engineer’s Surveys are recommended for newly built installations or installations with minimal damages.

Non-Compliance Surveys consists of inspecting each pallet location and noting each defect visible at the location. Non-Compliance Surveys are recommended for existing installations with appreciable damages present; these inspections are useful to gauge the number of repairs required and compare to quotes offered by repair contractors.

2. STORAGE CONSULTATION

- Evaluation of storage structures to safely support design loads or “Safe Working Loads (SWLs)”

- Design evaluation and confirmation for new structures and installations prior to the commencement of construction

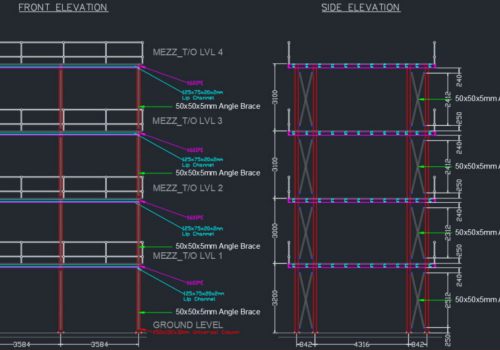

- Mezzanine Systems

- Cantilever Racking Systems

- Drive-In Racking Systems

- Rack Clad Structures

- Static Racking Systems

- Flow Racking Systems

- Mobile Base Racking Systems

3. DESIGN CHECKS

- Evaluation of existing storage structures to safely support design loads or “Safe Working Loads (SWLs)”

- Design evaluation and confirmation for existing structures and installations

- Non-compliance inspection and reporting for existing installations with a focus on installation compliance to accepted standards specifications

- Proposals for maintenance, repair, and retrofitting work to ensure the installation can safely support design loads

4. ERECTION COMPLIANCE

Reduced SWL capacity associated with poor installation practices will lead to a compromise on the safe use of the installation and in extreme cases racking collapse after loading.

BMH has on several occasions observed the difficulty incurred by installation teams to repair a poorly built system – not to mention the costs, loss in productivity, and potentially hazardous situations which result.

BMH places extreme emphasis on ensuring an installation is to standard prior to loading and issuing of an Engineer’s Certificate to protect all parties and ensure a properly working, safe system.

5. FABRICATION COMPLIANCE

We offer services in determining compliance of manufactured component to allowable tolerances and specifications.

Applicable international standards recommend physical testing in order.

6. REPAIR COMPLIANCE

7. RACK CERTIFICATION

8. SPECIALISED DESIGN SERVICES

MEZZANINE FLOORING

CANTILEVER RACKING

DRIVE-IN RACKING

The team at BMH are well acquainted with drive-in racking systems having designed new, and evaluated existing, drive-in racking structures across sub-Saharan Africa – issuing Engineering Certification to installations suitably designed and installed, or retrofitted.